| Sign In | Join Free | My howtoaddlikebutton.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My howtoaddlikebutton.com |

|

Brand Name : ZMSH

Model Number : Silicon carbide seed wafer

Place of Origin : China

Delivery Time : 2 weeks

Payment Terms : 100%T/T

Bow/Warp : ≤50um

Resistivity : High/Low Resistivity

Orientation : On-Axis/Off-Axis

TTV : ≤2um

Type : 4H

Diameter : 2inch 4inch 6inch 8inch

Particle : Free/Low Particle

Material : Silicon Carbide

4H SiC Seed Wafer Thickness 600±50μm <1120> Customization Silicon carbide growth

SiC seed crystal is actually a small crystal with the same crystal orientation as the desired crystal, which serves as the seed for growing a single crystal. It is also known as a crystal seed. By using seed crystals with different crystal orientations, crystals with different orientations can be obtained. Therefore, they are categorized based on their purposes: CZ-pulled single-crystal seed crystals, zone-melting seed crystals, sapphire seed crystals, and SiC seed crystals. In this issue, I will mainly share with you the production process of silicon carbide (SiC) seed crystals, including the selection and preparation of silicon carbide seed crystals, growth methods, thermodynamic properties, growth mechanisms, and growth control.

1. Wide band gap

2. High thermal conductivity

3. High critical breakdown field strength

4. High saturation electron drift rate

| Silicon carbide seed wafer | |

| Polytype | 4H |

| Surface orientation error | 4°toward<11-20>±0.5º |

| Resistivity | customization |

| Diameter | 205±0.5mm |

| Thickness | 600±50μm |

| Roughness | CMP,Ra≤0.2nm |

| Micropipe Density | ≤1 ea/cm2 |

| Scratches | ≤5,Total Length≤2*Diameter |

| Edge chips/indents | None |

| Front laser marking | None |

| Scratches | ≤2,Total Length≤Diameter |

| Edge chips/indents | None |

| Polytype areas | None |

| Back laser marking | 1mm (from top edge) |

| Edge | Chamfer |

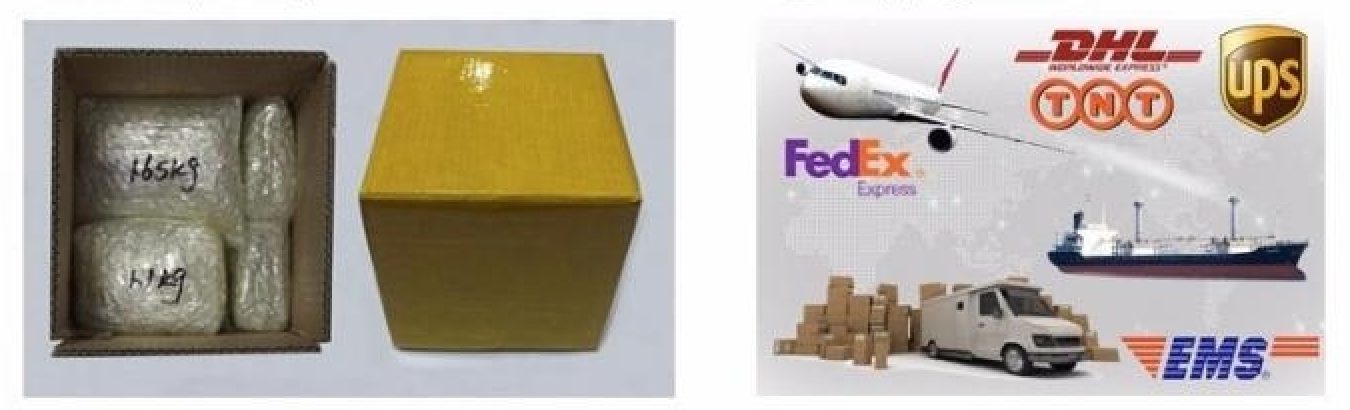

| Packaging | Multi-wafer cassette |

The silicon carbide seed crystal is used for preparing silicon carbide.

Silicon carbide single crystals are typically grown using the physical vapor transport method. The specific steps of this method involve placing silicon carbide powder at the bottom of a graphite crucible and positioning a silicon carbide seed crystal at the top of the crucible. The graphite crucible is then heated to the sublimation temperature of silicon carbide. The silicon carbide powder decomposes into vapor-phase substances such as Si vapor, Si2C, and SiC2. These substances sublime towards the top of the crucible under the influence of an axial temperature gradient. Upon reaching the top, they condense on the surface of the silicon carbide seed crystal, crystallizing into a silicon carbide single crystal.

The diameter of the seed crystal needs to match the desired crystal diameter. During growth, the seed crystal is fixed at the top of the crucible using an adhesive.

1.6inch Dia153mm 0.5mm monocrystalline SiC Silicon Carbide crystal seed Wafer or ingot

2.4h-N 100um Silicon Carbide Abrasive Powder For SIC Crystal Growth

|

|

4H SiC Seed Wafer Thickness 600±50μm <1120> Customization Silicon Carbide Growth Images |